Stainless Steel Tank Fabricators

At Northern Manufacturing, we specialize in fabricating stainless steel tanks of all shapes and sizes, catering to various industries such as Food & Beverage, Waste Water Treatment, Mining, Paper & Pulp, and more. Our expertise ensures that every tank meets the highest standards of quality and durability. Explore our capabilities in pipe welding and laser welding.

Forming Highlights

ASME IX CWI and Certified Welders

We are certified in GTAW, GMAW, and PMAW ensuring the highest standards in welding quality and safety.

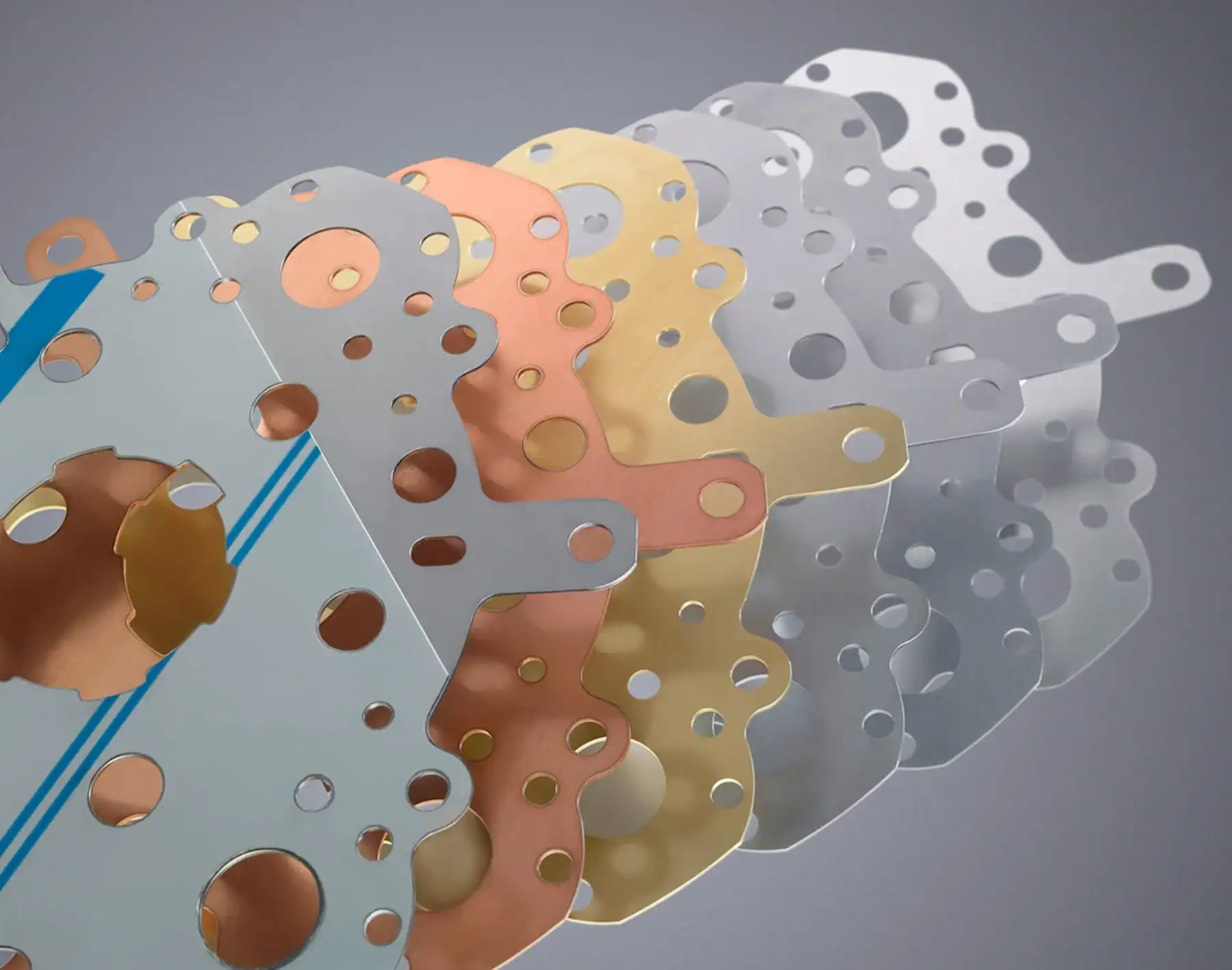

Laser Welding

Our advanced laser welding technology allows us to fabricate very large sheets efficiently and cost-effectively.

Large Laser Bed

Our 20′ laser bed enables us to cut larger parts and reduce weld seams, improving the structural integrity and quality of our tanks.

Capabilities

Huge Laser Bed

Parts up to 20′ Long

Huge opportunities exist to reduce cost with a large format laser. One customer was able to combine parts and eliminate welding in a part that had tight tolerances. Not only was the price of the part reduced, but the quality issues from weld distortion were eliminated.

Rolling

We have 3 plate rolls and a large capacity angle roll. This allows us to roll cylinders up to 10′ long and 1/2″ thick. Our operators have the experience to hold tight tolerances and roll odd shapes, such as ovals or cones.

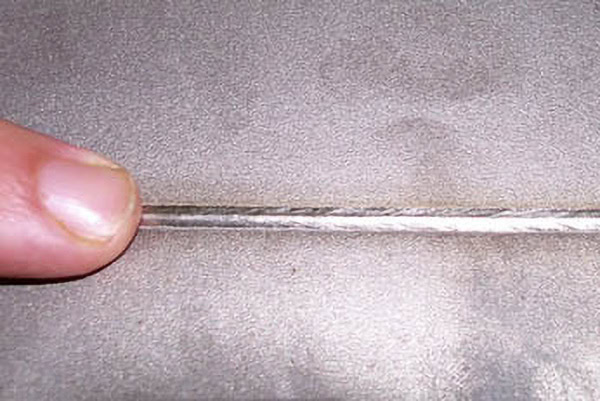

Hybrid Laser Welding

GMAW wire feed + Laser Welding

Hybrid laser welding is useful for very specific applications when filler metal is required. The laser beam is combined with the MIG welding weld puddle to push the molten filler metal deep into the weld joint. This process adds more heat and distortion than autogenous laser welding. It is generally used when the alloying filler metal is required for corrosion or strength, but can also be used to increase the weld speed or depth of penetration.

Food and Beverage Applications

Northern’s strategy for building food grade tank minimizes costs while maintaining very high quality standards. Material handing and automated welding minimize grinding and polishing costs down stream.

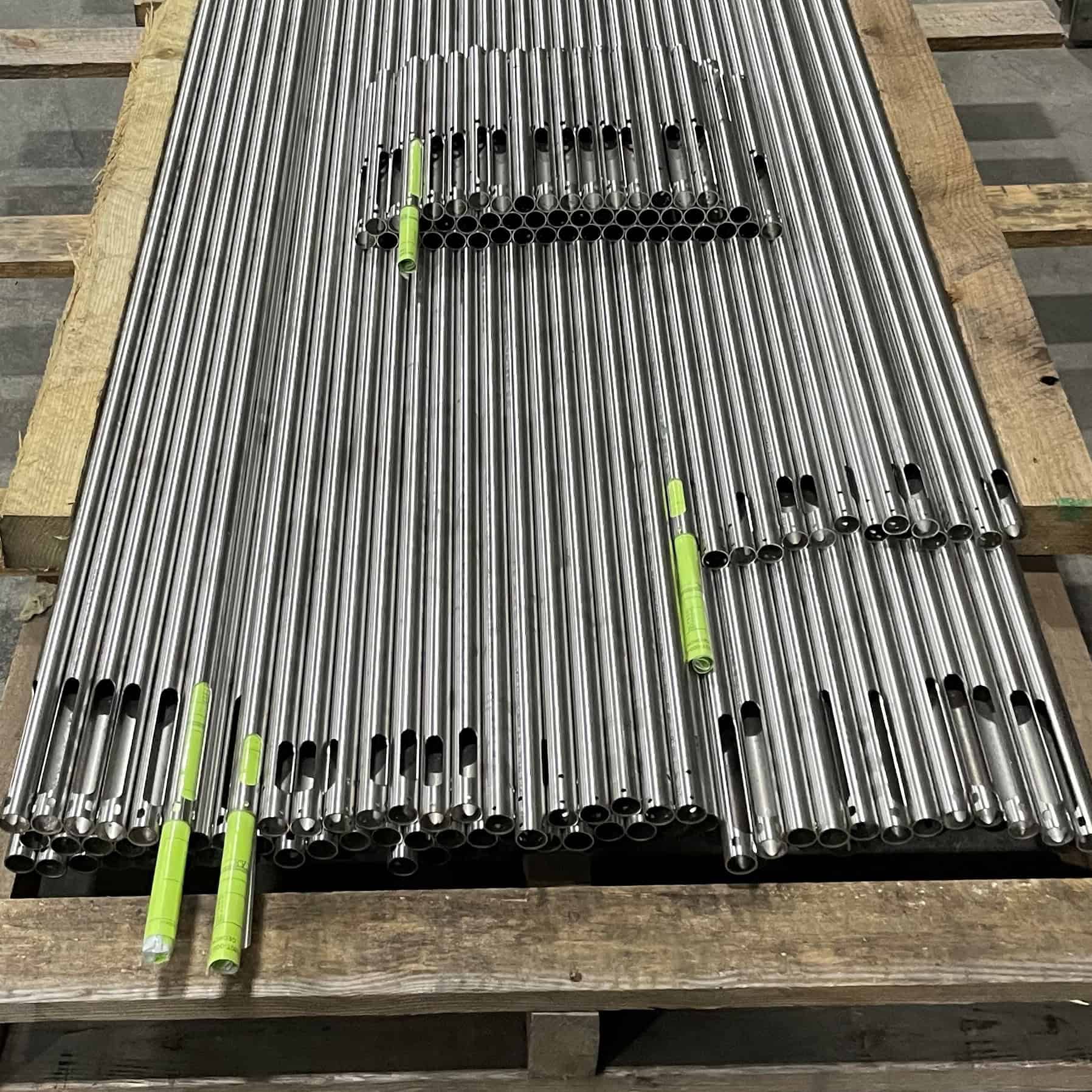

Who Uses Our Tube Laser Cutting Services?

Fabricators

Parts drop right into your fixtures or weld jigs

OEMs

Pre-cut kits for weld or bolt-together assemblies

Food & Sanitary

Critical applications requiring smooth, clean interiors.

Machine Builders

Bracketed frames with slot-tab alignment

Contract Manufacturers

Small run parts, ready for subassembly

Automotive

Large-scale ductwork, stacks, and housings for scrubber and air handling systems.

Ready to Get Started with

5-Axis Laser Cutting?

Whether you need one part, a full kit, or custom fabrication — our team will help you move fast and build smart.

Beyond Tube: Explore All Our Laser Capabilities

High-speed fiber and CO₂ flat laser cutting for sheet, plate, and nested part jobs.

3D laser cutting for large diameter, formed parts, bevels, and complex geometries.

Laser welding allows full penetration welds with low heat input, perfect for stainless steel fabrication projects.