Stainless Steel Fabrication: Built

Into Everything We Do

Stainless Steel Fabrication is at the core of everything we do. From oting and planning to welding, cleaning, and final inspection, Northern Manufacturing is built from the ground up to deliver clean, onsistent, high-performance stainless steel fabrications for critical ndustries.

Dedicated 40,000 SQFT Building for Stainless Steel Fabrication

40,000 sq ft building engineered to protect stainless steel from cross-contamination and quality loss.

Why it matters: Cross-contamination is a critical risk in stainless steel fabrication—one that many job shops overlook. Our environment is built to protect finish quality, corrosion resistance, and compliance from the start. Whether you’re in pharma, food, water, or OEM systems, this level of discipline ensures your product performs—and passes inspection in critical stainless steel fabrications.

Stainless Material Processing

We specialize in processing stainless steel—from common grades to high-nickel and duplex alloys—using clean handling, traceability, and tooling designed to preserve finish and integrity.

Processing Technologies

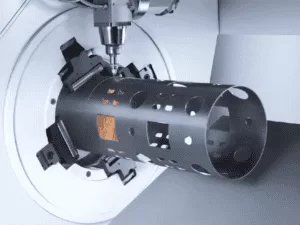

Master Craftsmen in Stainless Steel Fabrication

Our welders are masters of reducing heat input and eliminating distortion. Weld automation improves weld quality and consistency.

Advanced robotic welding cells with tools tailored specifically for stainless steel fabrication.

World class fabricators and master craftsmen are experts in stainless steel fabrication.

Laser welding allows full penetration welds with low heat input, perfect for stainless steel fabrication projects.

Who We Build For

With over 74 years of stainless steel fabrication experience, Northern is trusted by engineers, OEMs, and procurement teams across a wide range of stainless-intensive industries.

Water and Wastewater Treatment

Fabrication for clarifiers, skimmers, tanks, and flow control systems—built to resist corrosion in harsh, wet environments.

Food Processing

Sanitary weldments and high-finish assemblies for USDA-regulated applications, made to pass inspections and perform in washdown zones.

Industrial Equipment & Machinery

Custom stainless enclosures, frames, hoppers, and skids for heavy-duty equipment manufacturers.

Construction & Infrastructure

Structural stainless steel, platforms, supports, and project-specific metal components.

High Heat Applications- Ovens, Furnaces, Glass

Specialty alloys for elevated temperature exposure—317, 321, 347

Air Filtration and Pollution Control

Large-scale ductwork, stacks, and housings for scrubber and air handling systems.

Pulp, Paper & Recycling Equipment

Heavy-gauge stainless weldments for rugged, high-moisture processing environments.

Architectural and Structural tainless

Visible stainless work with high visual and structural requirements—precision formed, cleanly welded.

Power and Process Piping

Pipe spools, skids, and tank assemblies fabricated to ASME spec with CWI oversight and traceability.