Duplex Stainless Fabricatiors

Our experience fabricating duplex stainless steel ranges from 2003 lean duplex to 2507 super duplex alloys.

Forming Highlights

ASME IX CWI and Certified Welders

We are certified in GMAW, FCAW, GTAW and Hybrid Laser Welding

Hybrid Laser Welding

Cutting edge welding technology ensures great welds with proper phase balance.

Ferrite Measurement

Our ferrite scope alloys us to perform NDT of welds to verify phase balance during production.

Duplex Alloys:

Large Tonnage Press Brake Bending

The extreme tensile strengths of duplex stainless steels require extra large equipment for proper bending and forming. Northern’s 24′ press brake offers 660 tons of crushing force.

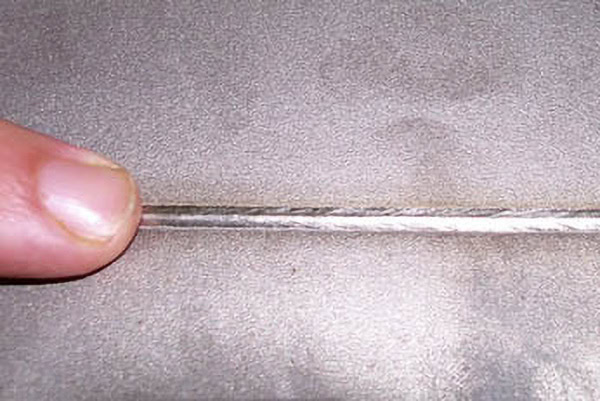

Hybrid Laser Welding

GMAW wire feed + Laser Welding

Hybrid laser welding is useful for very specific applications when filler metal is required. The laser beam is combined with the MIG welding weld puddle to push the molten filler metal deep into the weld joint. This process adds more heat and distortion than autogenous laser welding. It is generally used when the alloying filler metal is required for corrosion or strength, but can also be used to increase the weld speed or depth of penetration.

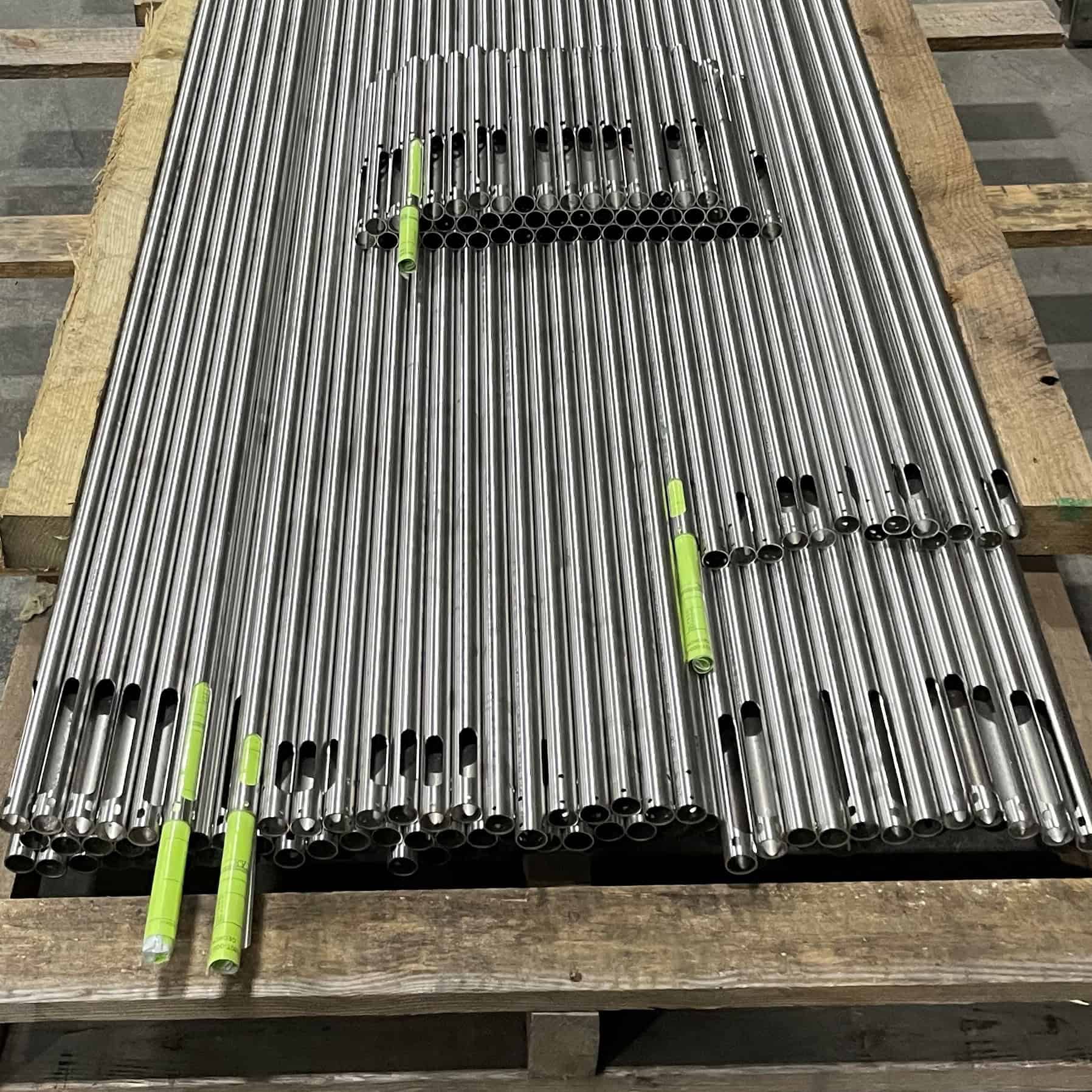

Who Uses Our Tube Laser Cutting Services?

Fabricators

Parts drop right into your fixtures or weld jigs

OEMs

Pre-cut kits for weld or bolt-together assemblies

Food & Sanitary

Critical applications requiring smooth, clean interiors.

Machine Builders

Bracketed frames with slot-tab alignment

Contract Manufacturers

Small run parts, ready for subassembly

Automotive

Large-scale ductwork, stacks, and housings for scrubber and air handling systems.

Ready to Get Started with

duplex stainless fabrication?

Whether you need one part, a full kit, or custom fabrication — our team will help you move fast and build smart.

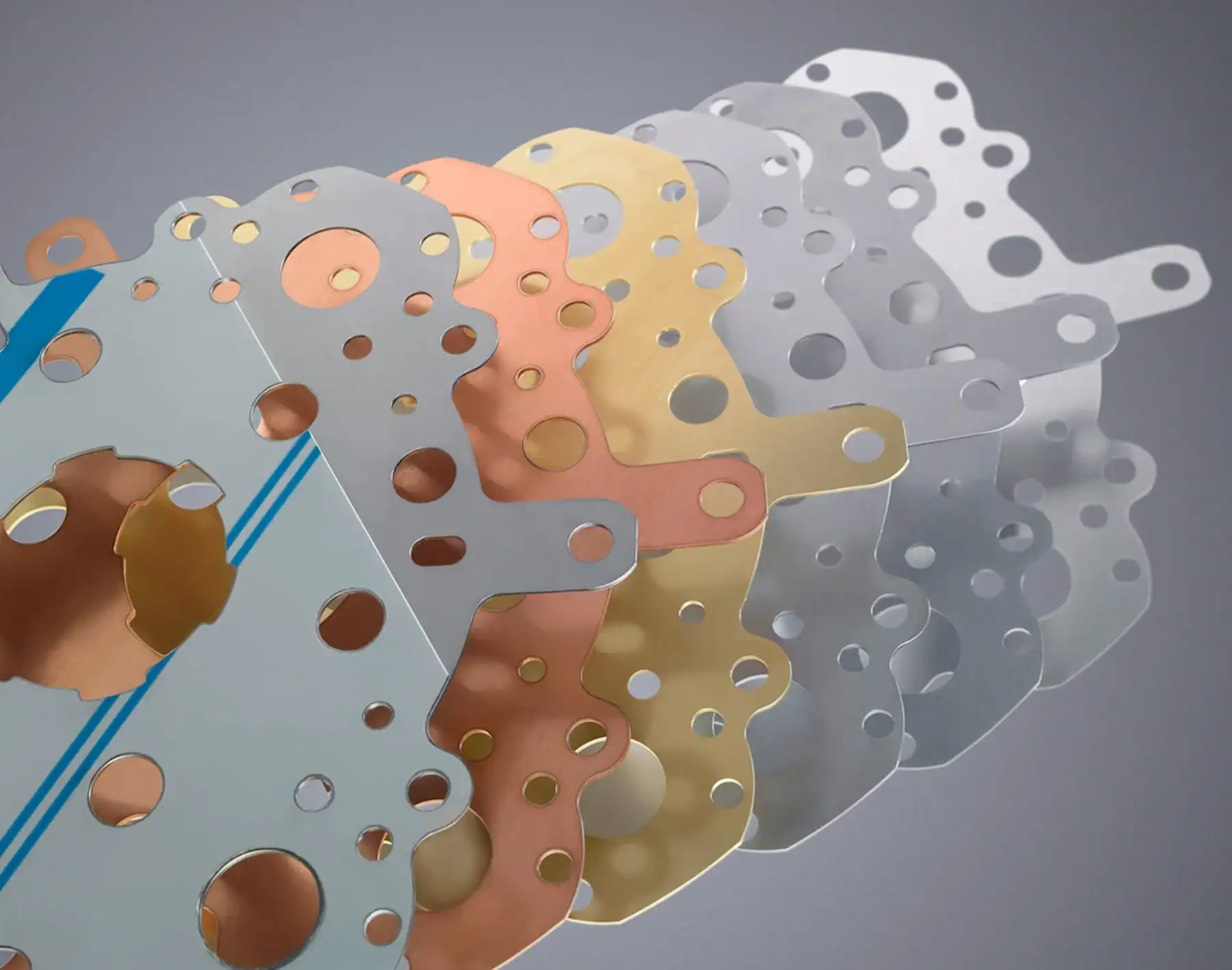

Beyond Tube: Explore All Our Laser Capabilities

High-speed fiber and CO₂ flat laser cutting for sheet, plate, and nested part jobs.

3D laser cutting for large diameter, formed parts, bevels, and complex geometries.

Laser welding allows full penetration welds with low heat input, perfect for stainless steel fabrication projects.