Custom Beam Fabrication Stainless Steel & Carbon

Northern’s unique robotic welding cell allows us to build custom size and shape beams that are not readily available on the market.

Custom Beam Advantages

Automation Reduces Costs

Welders are currently in short supply in the workforce. Robotic welding allows one programmer to match the output of more than 3 welders, across multiple robots and multiple shifts.

High Productivity

Our weld cycle times are often limited by how fast we can load parts into the Robot cell and hit GO. Setups often involve multiple weld fixtures for each robot, so that the robot can keep welding while parts are loaded and unloaded parallel to production.

Improved Weld Quality

Laser vision systems allow us to push robotic weld quality to new levels. Robots have always made consistent welds, but the weld quality was only as good as the consistency of the parts entering the weld cell. No longer are robots blind and dumb. The laser vision system allows the robot to adapt the weld path to match the part tolerances, eliminating weld rework.

Robotic Welding Capabilities

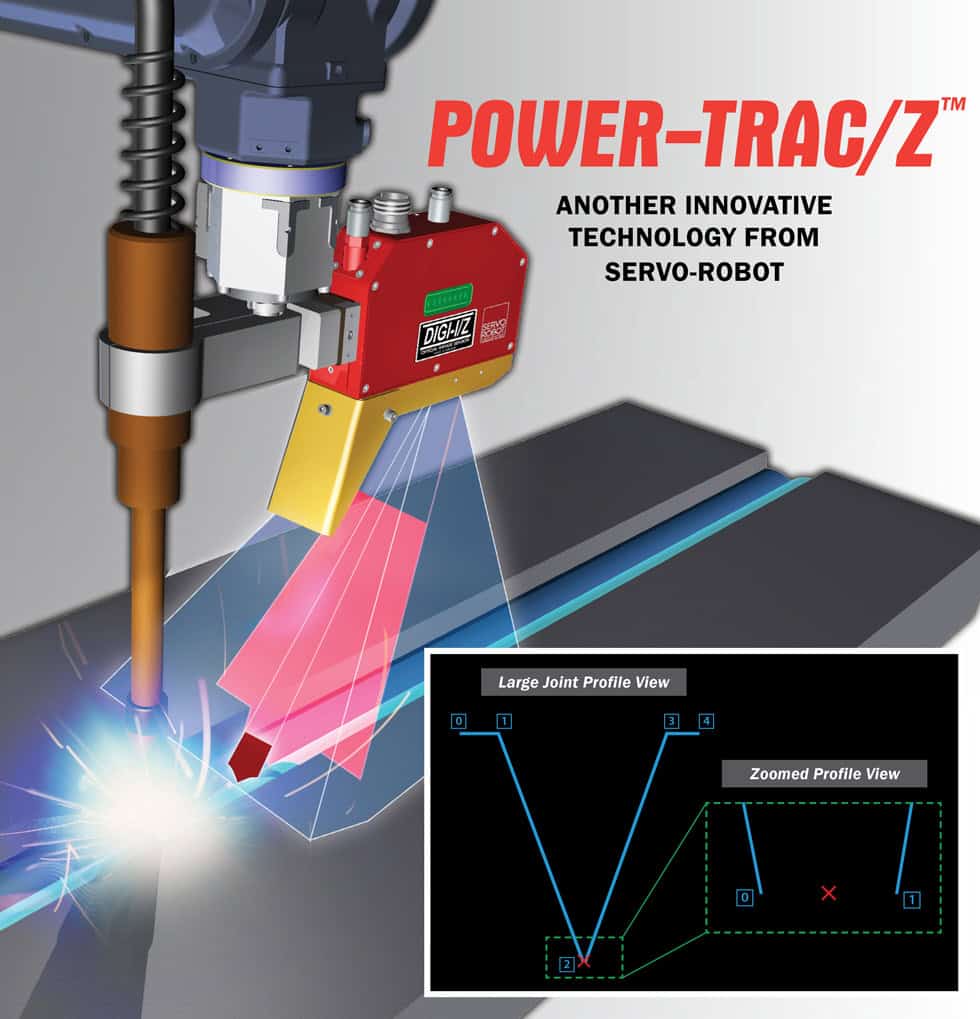

Laser Vision Systems

Our robots can now “see” the weld joint and adapt in real time. This eliminates weld quality issues do to part-to-part variation and also allows the robot to adapt to the part as heat distorts the shape of the work piece.

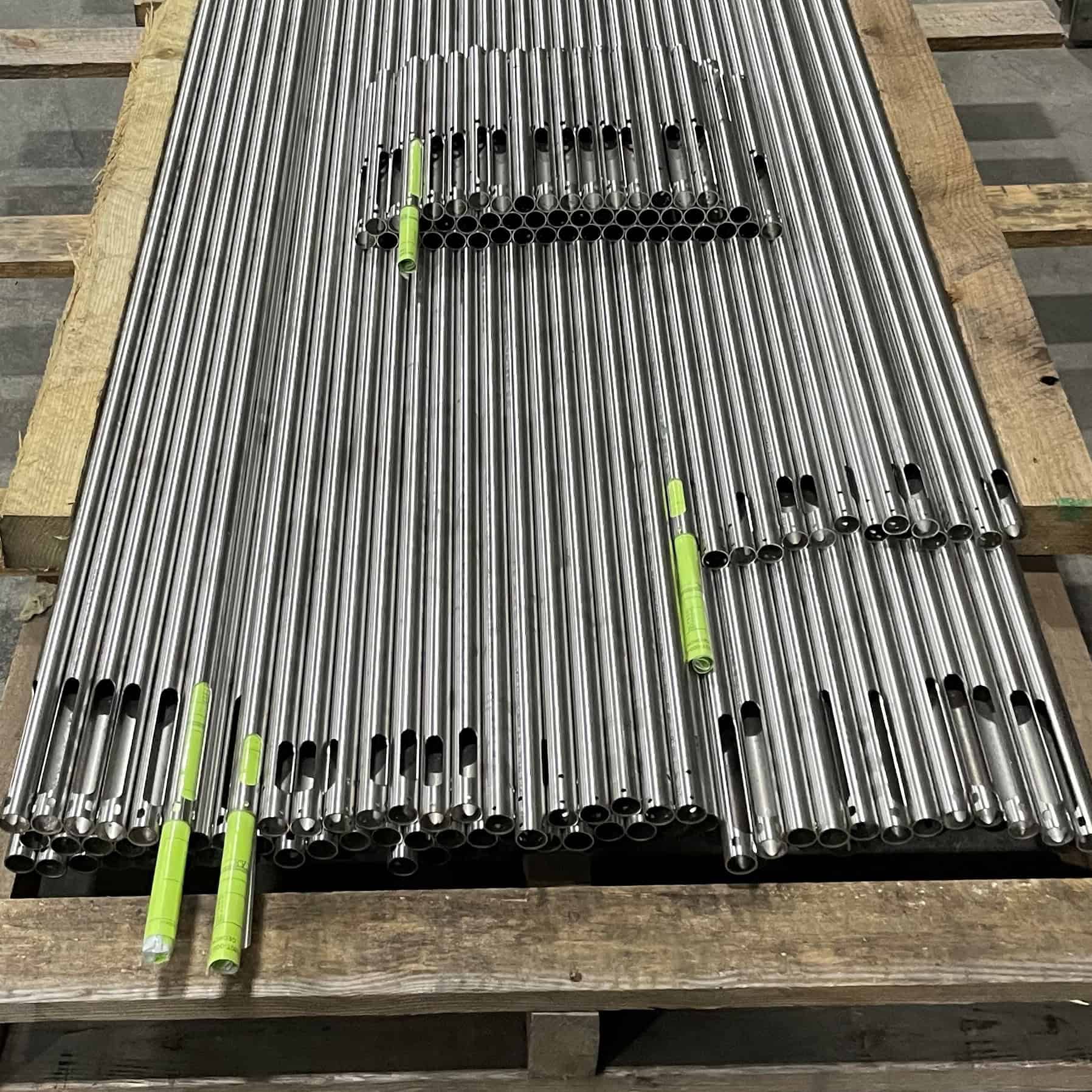

Who Uses Our Tube Laser Cutting Services?

Fabricators

Parts drop right into your fixtures or weld jigs

OEMs

Pre-cut kits for weld or bolt-together assemblies

Food & Sanitary

Critical applications requiring smooth, clean interiors.

Machine Builders

Bracketed frames with slot-tab alignment

Contract Manufacturers

Small run parts, ready for subassembly

Automotive

Large-scale ductwork, stacks, and housings for scrubber and air handling systems.

Ready to Get Started with

5-Axis Laser Cutting?

Whether you need one part, a full kit, or custom fabrication — our team will help you move fast and build smart.

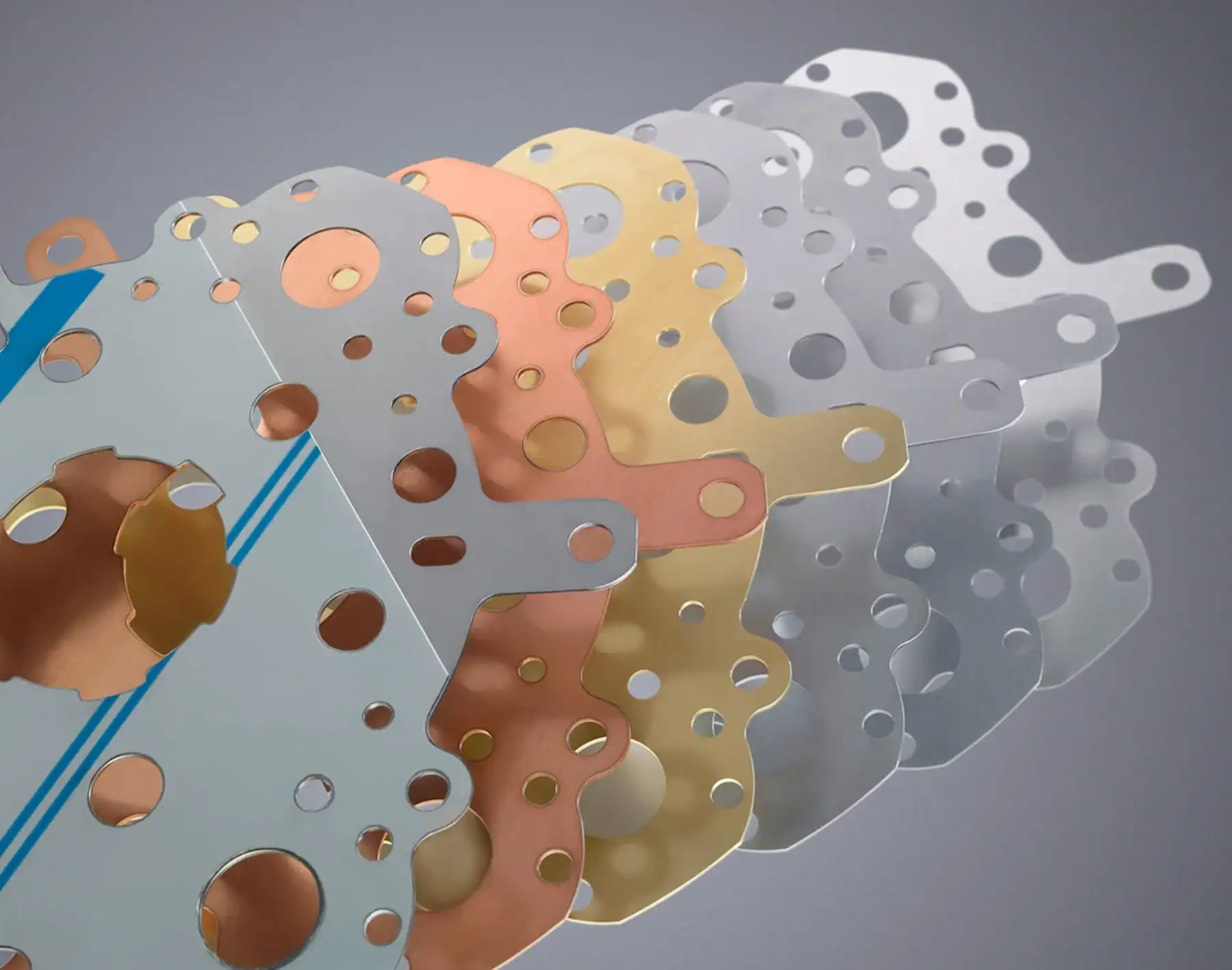

Beyond Tube: Explore All Our Laser Capabilities

High-speed fiber and CO₂ flat laser cutting for sheet, plate, and nested part jobs.

3D laser cutting for large diameter, formed parts, bevels, and complex geometries.

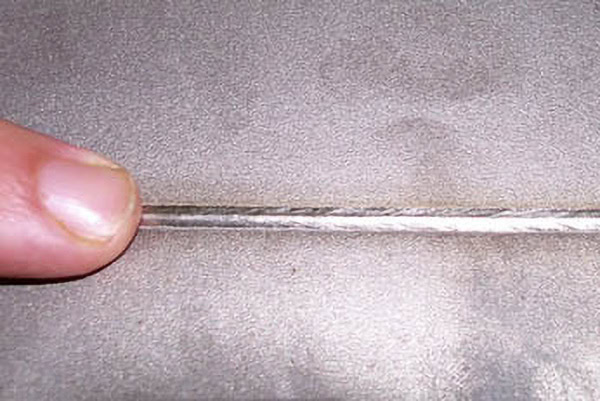

Laser welding allows full penetration welds with low heat input, perfect for stainless steel fabrication projects.