Stainless Steel Bead Blasting Services

The 34′ x 16′ blast booth adds a new cosmetic finishing option to our toolbox.

Why Bead Blast Stainless Steel?

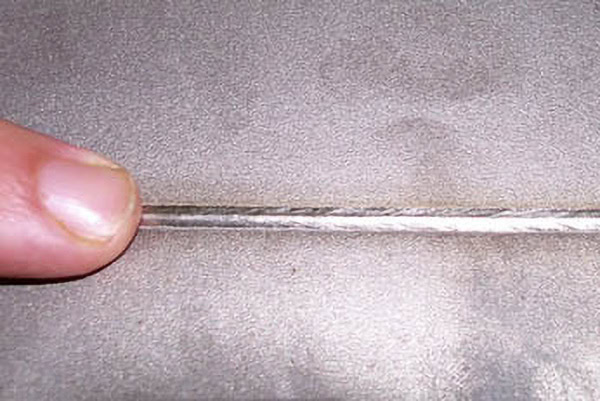

Uniform, Non-Directional Finish

Bead blasting provides a consistent matte finish that contrasts well with other highly polished finishes.

Improve Stress Corrosion Resistance

The peening action of bead blasting stainless steels will cause them to both work harden and stress relieve the metal. This can improve the stress corrosion cracking resistance on austenitic stainless steels.

No Carbon Contamination

The blast booth and media are nonferrous zones. Carbon steel parts are never processed in the blast booths, and the blast media is monitored for any outside contamination.

Capabilities

Bead Blast Finish

The matte, bead blast stainless finish is a great aesthetic for the food service or pharmaceutical industry. The process hides small surface defects from material handling and gives a beautiful uniform finish. The surface roughness can be less then 1.0 µm

Spray Pickling & Blasting

It is desirable to spray pickle stainless steel to remove all weld discoloration and the chromium depleted layer, so that the corrosion resistance of the stainless is fully restored. Bead blasting will remove weld discoloration as well, but not as completely or as accurately as pickling. Northern can offer the ideal process – spray pickling followed by bead blasting – in one location for a low total cost.

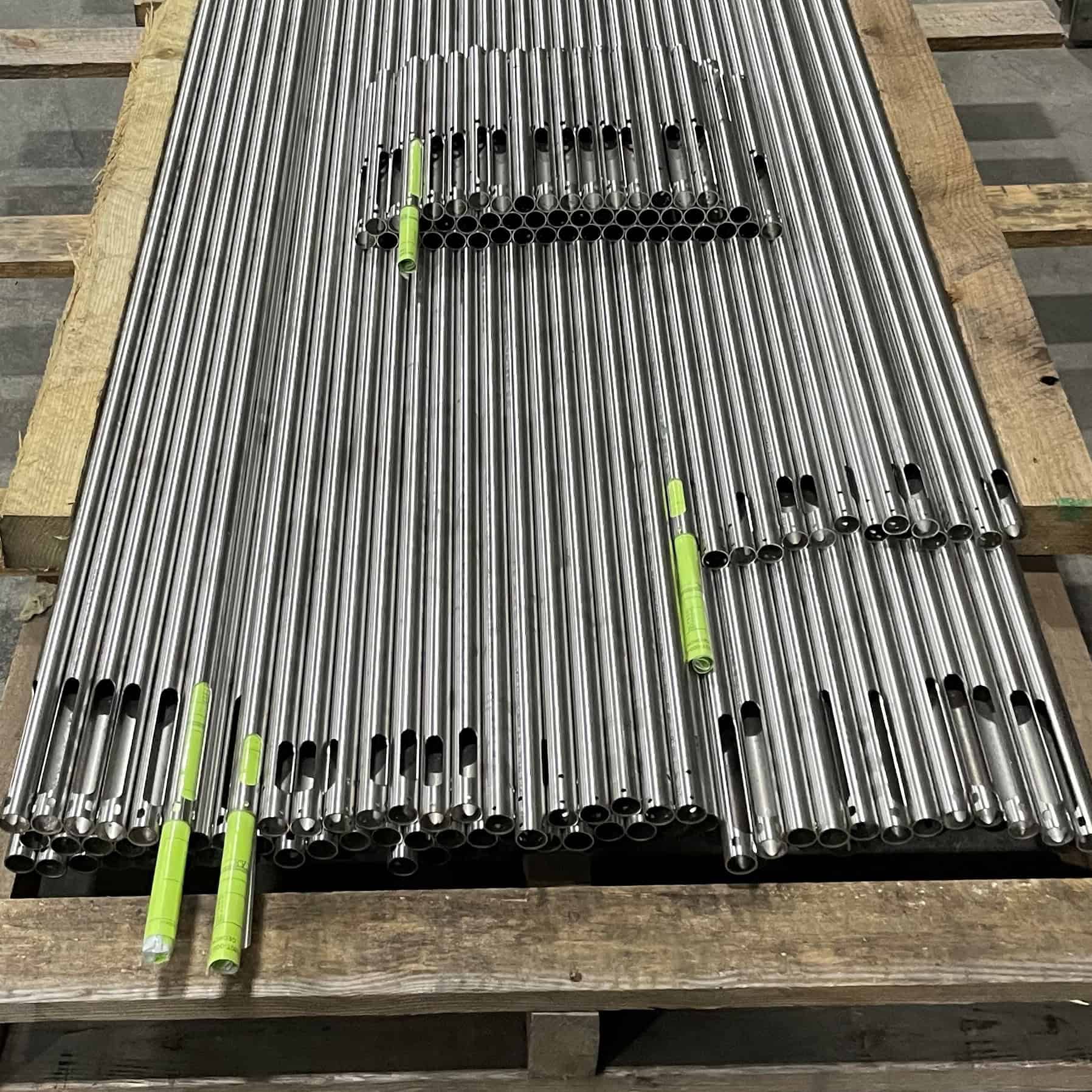

Who Uses Our Tube Laser Cutting Services?

Fabricators

Parts drop right into your fixtures or weld jigs

OEMs

Pre-cut kits for weld or bolt-together assemblies

Food & Sanitary

Critical applications requiring smooth, clean interiors.

Machine Builders

Bracketed frames with slot-tab alignment

Contract Manufacturers

Small run parts, ready for subassembly

Automotive

Large-scale ductwork, stacks, and housings for scrubber and air handling systems.

Ready to Get Started with

5-Axis Laser Cutting?

Whether you need one part, a full kit, or custom fabrication — our team will help you move fast and build smart.

Beyond Tube: Explore All Our Laser Capabilities

High-speed fiber and CO₂ flat laser cutting for sheet, plate, and nested part jobs.

3D laser cutting for large diameter, formed parts, bevels, and complex geometries.

Laser welding allows full penetration welds with low heat input, perfect for stainless steel fabrication projects.