AWS & ASME Certified GTAW and GMAW Welding

The foundation for Northern’s growth for the last 40 years is high quality welding. Our 50+ welders handle projects from 24GA stainless to 1″ Carbon – and everything in between.

Our Welding Skill Set

Heat and Distortion Control

Stainless steel, aluminum, and carbon steel behave very differently when welded. Our team’s experience allows us to hold extremely tight tolerances despite these challenges.

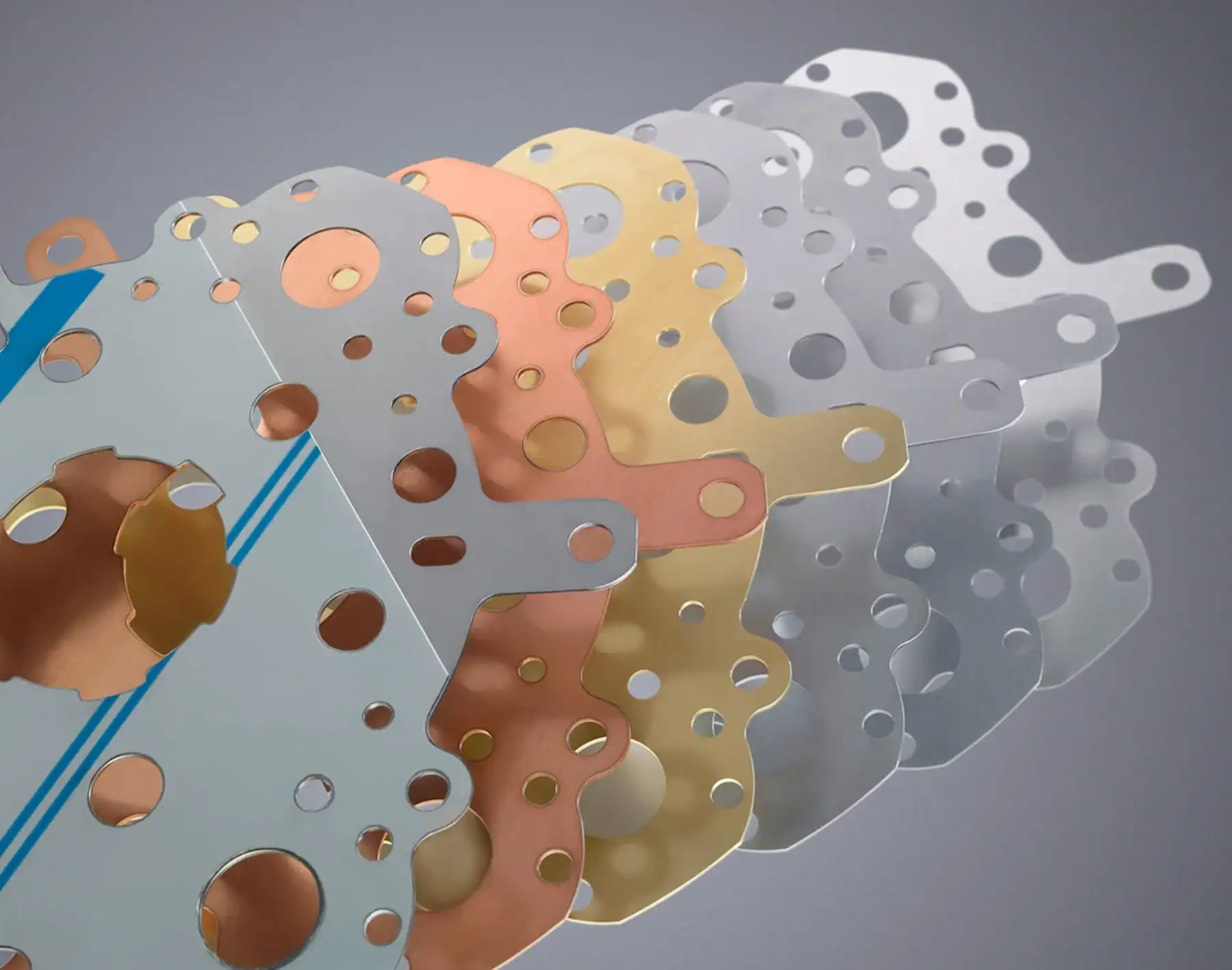

From Thin to Thick, from A36 Steel to AL6XN Stainless

It’s rare that a project is outside of our comfort zone. Material thicknesses from 0.020″ to 1″, and various materials and alloys of Stainless, Aluminum, and Carbon steel are all in our wheel house.

Cosmetic and Structural

Our certified welders don’t just “pass code.” Their welds must both be structurally sound and aesthetically pleasing.

Welding Capabilities

Material Examples

Stainless Alloys

- Austenitic – 304, 309, 316, 317, 321, 347

- Ferritic – 409, 430

- Duplex – 2205, 2003

- Super Alloy – 904, AL6XN, C22, C276

Aluminum Alloys

- 5XXX – 5052, 5083, 5086

- 6XXX – 6061, 6062, 6063, 6082

Carbon Steels

- Structural Steels – A36, A1018, A500, A572

- Sheet Steels – A1008, A1011, Corten

- Coated Steel – Aluminized, Galvanized

AWS and ASME Code Welding

Certified Welding Inspectors On Staff

A very large percentage of our projects now require AWS or ASME welding procedures (WPS). Most of our welders are certified in the basics – carbon steel and austenitic stainless steels – for both GMAW (MIG) and GTAW (TIG). Our top 1/3 of welders are qualified in more difficult alloys such as aluminum alloys and high nickle stainless steels.

Advanced Welding Technology

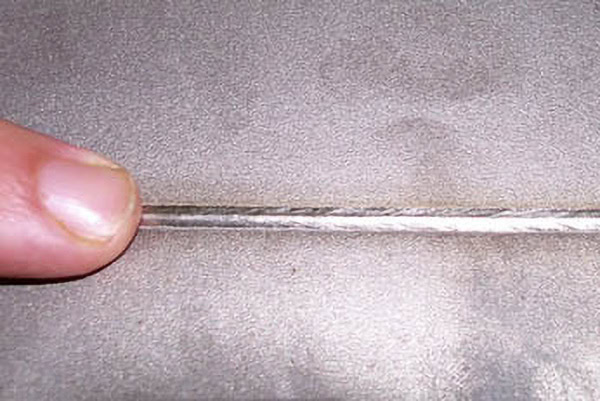

Wire Feed TIG Welding

A cold wire feed TIG process provides fast deposit rates and lower filler metal costs. The mechanized process can improve weld quality in the hands of a skilled operator. Cold wire feed is often preferred over MIG welding on projects where high quality welds are required but for the speed and lower cost of GMAW welding.

Aerospace D17.2 Spot Welding

Aerospace spot welding requires exacting procedures and careful quality assurance. Northern has experience with spot welding and pull testing stainless steels up to 12GA in thickness.

Aluminum Welding Equipment

Northern has a substantial investment in welding equipment designed for Aluminum welding. For GMAW, push-pull guns address the wire feeding issues associated with aluminum, and give the operator precise control over the heat input to the part. For GTAW, new digital pulse TIG machines make welding aluminum almost as easy as carbon or stainless steel.

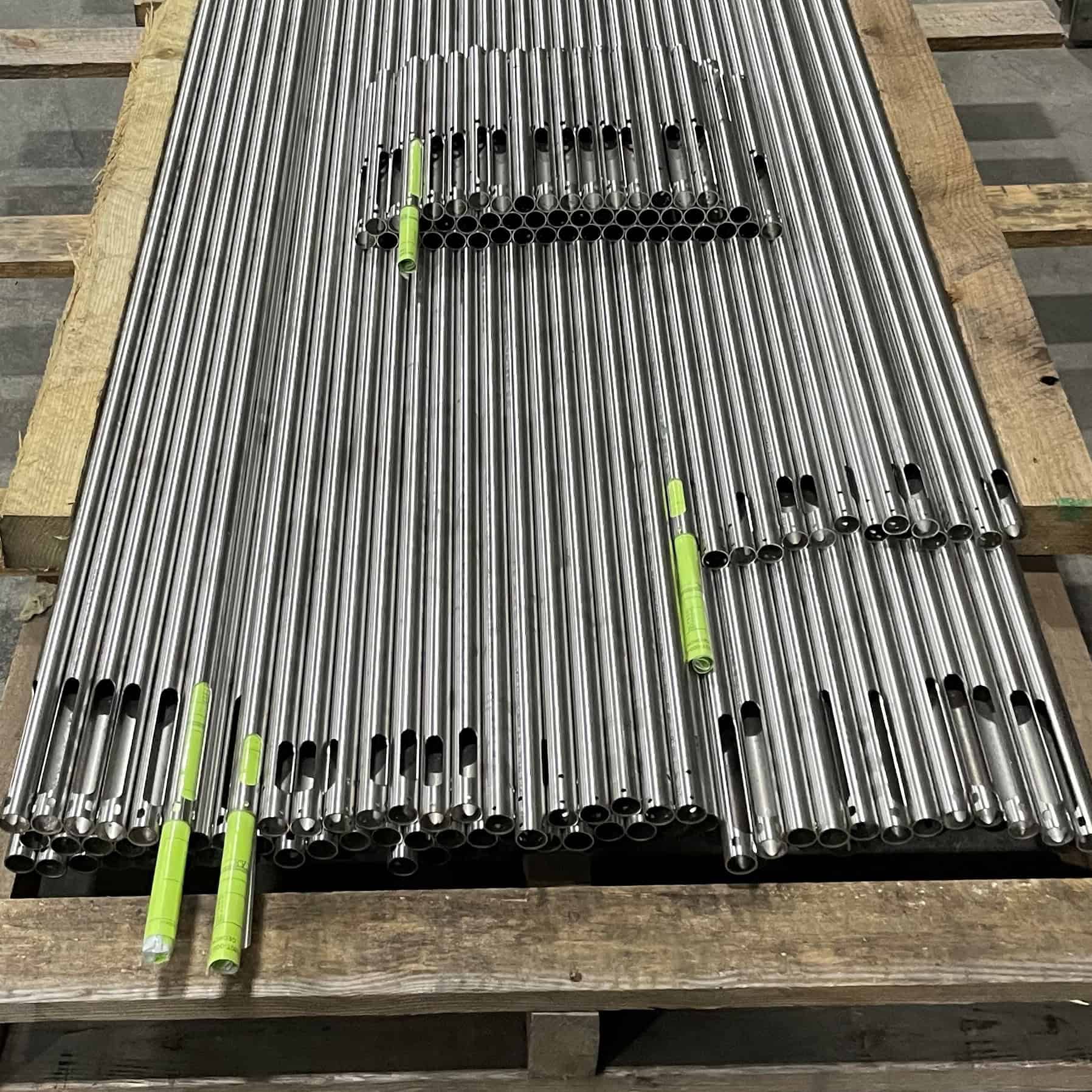

Who Uses Our Tube Laser Cutting Services?

Fabricators

Parts drop right into your fixtures or weld jigs

OEMs

Pre-cut kits for weld or bolt-together assemblies

Food & Sanitary

Critical applications requiring smooth, clean interiors.

Machine Builders

Bracketed frames with slot-tab alignment

Contract Manufacturers

Small run parts, ready for subassembly

Automotive

Large-scale ductwork, stacks, and housings for scrubber and air handling systems.

Ready to Get Started with

5-Axis Laser Cutting?

Whether you need one part, a full kit, or custom fabrication — our team will help you move fast and build smart.

Beyond Tube: Explore All Our Laser Capabilities

High-speed fiber and CO₂ flat laser cutting for sheet, plate, and nested part jobs.

3D laser cutting for large diameter, formed parts, bevels, and complex geometries.

Laser welding allows full penetration welds with low heat input, perfect for stainless steel fabrication projects.