Engineering: Design for Manufacturability

The engineering team at Northern specializes in taking customer designs and finding a new way to make a project utilizing our unique and advanced technology. This process often allow us to eliminate parts, welding and machining which can both lead to a savings in cost and improvement in quality.

Engineering Highlights

3D Model Every Part

3D modeling enables many things: programming machines, creating shop routing, and QC check our drawings with customer prints. We use the 3D models for project planning, re-design for manufacturing with our equipment, and document/revision control.

Hands-On Problem Solving

Engineers spend a great deal of time on the shop floor and have a thorough understanding of our machines and capabilities. Many improvements are made through small “tweaking” of designs, and occasionally their insight will yield a design breakthrough significantly changing the cost structure of the part.

Never Pick Up a Tape Measure

Smart design features can error proof assembly. This is all possible from thoughtful design decisions in engineering. While this adds time at the beginning of the process, it significantly improves productivity and quality.

Software and File Types

Locating Features

Error Proof Design

Locating features make it possible to design tight tolerances into a product without the use of fixtures. The CNC cutting equipment defines the location of parts to within 0.005″.

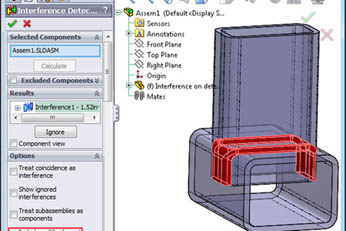

3D Modeling

From Customer to the Shop Floor

Every project is 100% 3D Modeled. This helps with our quality control, brainstorming, planning, and communication.

Who Uses Our Tube Laser Cutting Services?

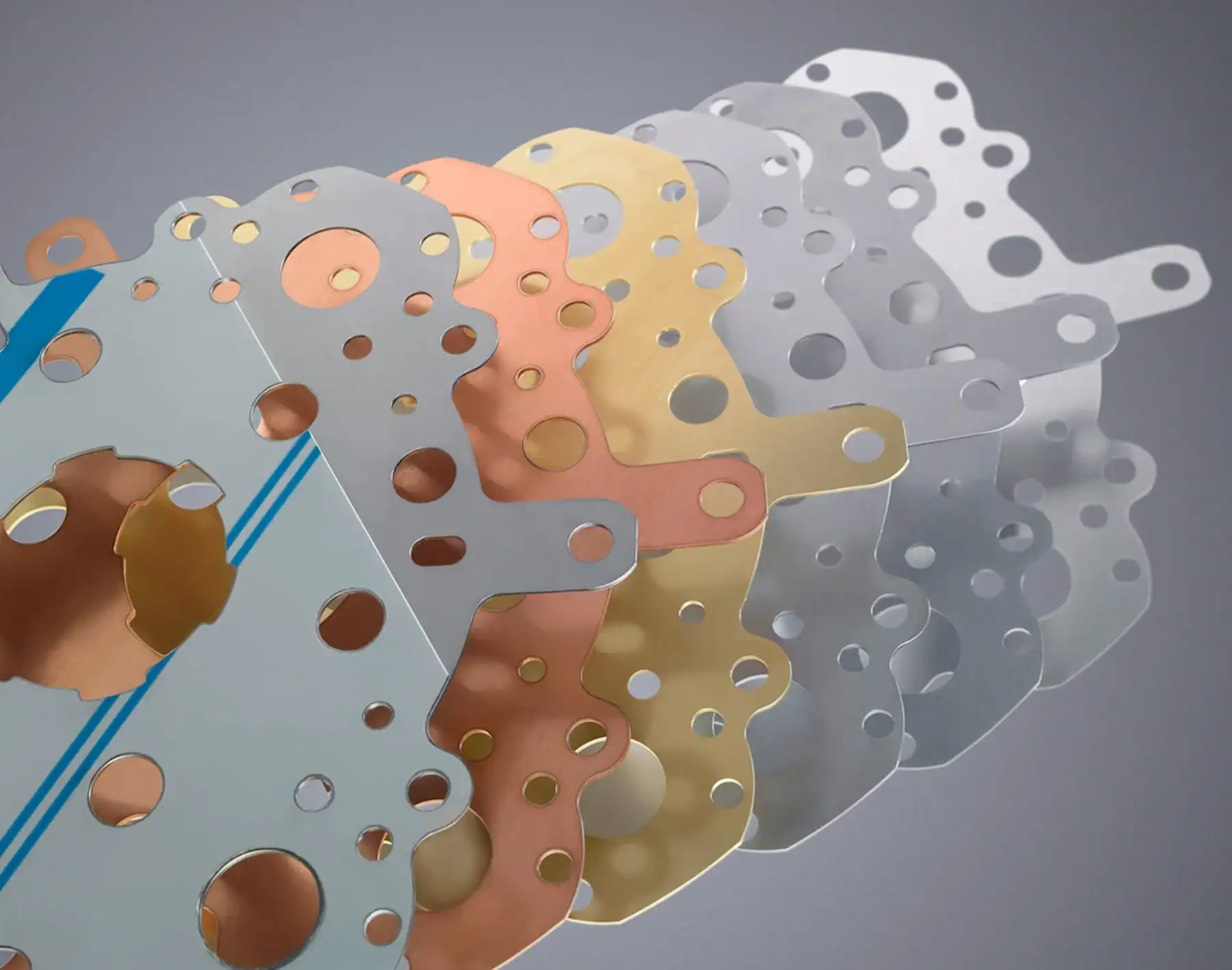

Sheet Metal and Tubing

Fixtureless Welding

Laser Etching

iPad 3D Models

3D Interference Checks

Quality Inspection

Ready to Get Started with

5-Axis Laser Cutting?

Whether you need one part, a full kit, or custom fabrication — our team will help you move fast and build smart.

Beyond Tube: Explore All Our Laser Capabilities

High-speed fiber and CO₂ flat laser cutting for sheet, plate, and nested part jobs.

3D laser cutting for large diameter, formed parts, bevels, and complex geometries.

Laser welding allows full penetration welds with low heat input, perfect for stainless steel fabrication projects.